Case background

In recent years, with the progress of society and the development of economy, science and technology, people's living, working and production levels have been greatly improved. People put forward higher requirements for production and life, and the monitoring of pump station is one of them. For the traditional water source well monitoring, the staff will check it regularly; Later, the RS485 monitoring scheme was adopted, but the wiring was very troublesome. At the same time, this method was very troublesome for the monitoring of multiple distributed water source wells. Therefore, in this context, the monitoring of unattended water source wells through wireless GPRS monitoring of pump stations came into being.

Scope of application

The system is suitable for remote monitoring and management of water source wells and pump stations.

system composition

The remote monitoring system of water source well is mainly composed of dispatching center, water source well monitoring center, communication platform, remote measurement and control terminal of water source well, metering and measurement (flowmeter, pressure sensor, liquid level sensor, etc.) equipment and control equipment (motor controller, etc.).

Composition of remote monitoring system for water source well

System functional features

The management personnel of the water source well can remotely monitor the liquid level in the well, the working state of the pump unit, pump flow, pump pressure, etc. in the water source well monitoring center; Support the manual control, automatic control and remote control of the pump starting equipment to start and stop the pump set, so as to realize the unattended operation of the water source well.

A. Hardware Introduction (rtu6100)

1. Wide voltage power supply range: 7v-30v, suitable for industrial occasions;

2. With RS232 and RS485 (when 232 is also converted to 485, there can be two 485 channels), it can be easily configured and RS485 network can be established;

3. 6 channels of ad analog input (12 bits), the input voltage is 0-30V, and it can also measure 4-20mA industrial current signal. Ad analog is suitable for collecting various sensor signals;

4. 6-way relay output control and 4-way optocoupler input and output control (the number of input and output bits is optional), which can be used for input and output occasions, such as motor startup;

5. Transmission supports a variety of protocols. Our company's self-defined protocol and Modbus Protocol (ASCII, RTU, Modbus TCP) perfectly support, and Modbus protocol perfectly supports configuration;

6. Data transmission adopts GSM module, which can realize the following functions:

a) GPRS disconnection automatic reconnection;

b) Up to 6 central servers can be connected at the same time as required;

c) Support the addressing mode of fixed IP, domain name resolution and APN private network;

d) Support TCP, UDP, PPP, ICMP, DNS, FTP and other protocols;

e) Reduce the cost of wiring and the trouble of construction;

f) Support SMS data transmission and SMS parameter configuration;

g) Support phone and SMS wake-up function;

7. Support special software for local and remote parameter configuration and maintenance;

8. Support local and remote firmware upgrade;

B. Software function

Remotely monitor the water level of water source well, water pump pressure and water pump flow.

Remotely monitor the working state, current, voltage, protection state and working mode of the pump unit.

Remotely switch the control mode of the water pump and remotely control the start and stop of the pump set.

Support the storage and historical record query of various monitoring information, control information, alarm information and operation information.

Generate various data reports and data curves.

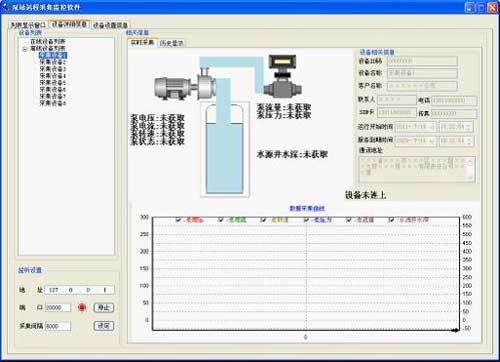

C. Software screenshot

real-time display

1. The device list on the left shows the information of current online and offline devices. When the device is connected to the network, it will enter the "online device list" from the "offline device list". If the device is not online for a long time, it will enter the "offline device list" from the "online device list";

2. The upper right corner displays the equipment number, user name, contact person, telephone, fax, mobile phone, SIM card number, address and other information;

3. The upper left corner displays the pump speed, pump current, water source well liquid level, pump flow, pump pressure and other information;

4. Under the window, the curves of pump speed, pump current, water source well liquid level, pump flow and pump pressure are displayed in real time;

5. The middle text prompts the current equipment login time and the last time of collecting and returning data;

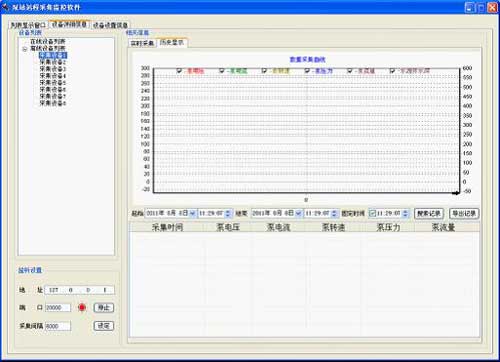

Historical records

1. Users can search history according to time period;

2. The history record will be drawn on the window in the form of curve, and the history record can be displayed under the window in the form of list. Through the history record, the equipment operation status and relevant trend can be viewed;

3. The history records queried at the same time can be exported to excel;

Effect drawing of configuration software

Users can customize the program through configuration software according to their needs, so that the interface expression form is more flexible;

Advantage characteristics

In case of voltage and current overrun, liquid level overrun, equipment protection and other conditions on site, the field controller can send alarm messages.

Manager Wang

Manager Wang

OfficialAccounts

OfficialAccounts