Case background

RTU is a measurement and control unit device installed in remote field, which is responsible for the monitoring and control of field signals and industrial equipment. It converts the measured state or signal into the data format that can be sent on the communication media and transmits it to the central computer. At the same time, it also converts the data sent from the central computer into commands to realize the functional control of the equipment. In the production process automation device, the remote measurement and control terminal RTU fully embodies the idea of "decentralized measurement and control and centralized management". Its advantages in improving the reliability of signal transmission, reducing the burden of host computer, reducing the amount of signal cable and saving installation costs have also been determined by users. It has been widely used in municipal pipe network, oil and gas fields, water conservancy, electric power, coal mine, transportation, energy management and other fields.

Most of the oil field pipeline valve chambers are in the field environment, and the natural environment is very bad. At ordinary times, the inspection of unattended pipeline conditions, temperature, pressure and other data in each valve chamber of the oil field pipeline valve chamber can only rely on manual inspection. However, due to the wide area and poor natural conditions, an inspection often takes more than half a day to complete, and the equipment failure can not be found in time. The application of RTU in this environment solves this problem very well.

Oil field valve chamber monitoring system

This system is a typical SCADA system, that is, monitoring data acquisition system. The system is composed of hardware equipment such as jy-rtu series remote measurement and control terminal based on GPRS / GSM network and industrial monitoring configuration software. The system is roughly divided into server, engineer station and operator station in the central control room, remote measurement and control terminal RTU of each oilfield pipeline valve room, communication network system and field primary measurement and control instrument. Its main structure consists of three levels: central computer management system, communication system and remote measurement and control terminal RTU. The block diagram of oilfield valve chamber monitoring system is as follows:

The system adopts the monitoring and data acquisition system with computer as the core. SCADA control system is set in the dispatching center, and a set of master station RTU (jy-rtu6640) is set. The system includes the remote control system of oilfield pipeline valve chamber composed of GPRS RTU. The tasks of diagnosis, monitoring and data acquisition of the control system of the valve chamber can be completed in the control room of the dispatching center.

Composition and characteristics of RTU

The remote measurement and control terminal adopts jy-rtu6640, which has RS232 and RS485 dual serial ports (there can be two 485 channels when 232 is also converted to 485), built-in high-capacity SPI flash (the capacity can be 1mbit-64mbit), realizes the long-term local storage of data, adopts 6-channel relay output control, 4-channel optical coupling input and output control, built-in RTC, automatic timing and fixed-point wake-up after power failure, supports standard Modbus protocol, and adopts GPRS / GSM network as the network platform, Independently complete the collection, control, communication, data processing, alarm upload, display, operation and other tasks of the oilfield pipeline valve chamber, and realize all functions of the system.

communication system

The communication system is divided into GPRS / CDMA wireless communication and satellite wireless communication.

1) GPRS / CDMA wireless communication mode

The data of GPRS DTU measurement and control terminal DTU is sent to the designated data center through the network. After receiving the DTU data, the data center will convert the protocol to restore the user data and manage the DTU at the same time. Realize the two-way flow of data.

2) Satellite wireless communication mode

The data of the field measurement and control terminal is connected with the satellite through the satellite transmitter to send the data. After connecting with the satellite receiver of the main station through the satellite, the protocol conversion is carried out to restore the user data and manage it at the same time. Realize the two-way flow of data.

Relevant monitoring data of oil field valve chamber

The valve chamber liquid intrusion alarm and access control switch are the monitoring of switching values. The collection of integrated transmitters such as pipe temperature, pipe pressure, ground temperature, natural gas concentration and battery power has the functions of upper and lower limit protection, sudden alarm, regular upload and transmission, etc.

system function

The main functions of the remote monitoring system of oil field pipeline valve chamber are completed by five parts: power supply, communication, data monitoring, isolation protection and computer centralized monitoring.

power supply

Due to the special location of the pipeline valve chambers in the oilfield, they are all in the wasteland and the on-site environment is relatively bad, they are unattended stations, and there is no lighting circuit in each valve chamber on site, so the power supply of instruments and control cabinets in the valve chamber adopts solar charging and battery power supply.

Communication part

At present, the distance between oil pipelines is relatively long. The valve chambers are scattered. Due to the long communication distance, the system adopts GPRS network. It realizes the real-time monitoring of the operation status of field equipment, and realizes the interworking and mutual transmission of data among personnel, control center and equipment, so that technicians and managers can get the data of each monitoring point anywhere and respond in time.

Data acquisition and remote control

GPRS RTU system is selected as the remote monitoring system of oilfield pipeline valve chamber to complete the functions of data acquisition, automatic control, parameter storage, real-time communication, fault alarm and so on. It can complete local control independently or be controlled by the monitoring center.

data acquisition

Upload the pipeline pressure, pipeline temperature, ground temperature, battery power, combustible gas concentration and flow, valve chamber access control and water inlet switch start and stop status, alarm parameters, patrol inspection records, etc. of each station to the central monitoring center.

Monitoring part

Receive the command from the monitoring center, set the time, parameters and procedures of the RTU of the remote valve chamber through the RTU of the master station, and upload and display the active data bidding and testing.

Parameter storage

Store accumulated flow, fault parameters and other important parameters such as pipeline pressure and temperature, and export historical records.

Fault alarm

Complete the out of limit alarm of operating parameters, anti-theft alarm and self diagnostic alarm of equipment.

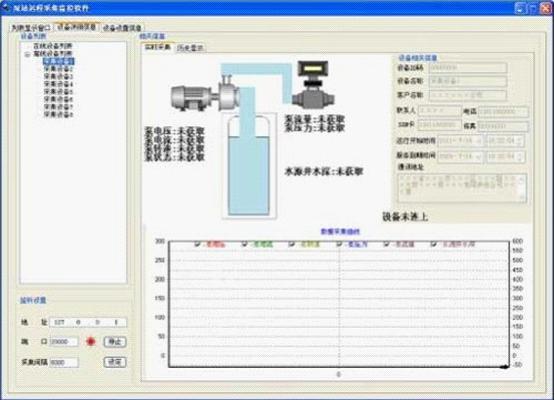

The software interface is as follows:

Historical records

1. Users can search history according to time period;

2. The history record will be drawn on the window in the form of curve, and the history record can be displayed under the window in the form of list. Through the history record, the equipment operation status and relevant trend can be viewed;

3. The history records queried at the same time can be exported to excel;

conclusion

In the project of oil field pipeline valve chamber monitoring system, due to the use of valve chamber distributed control system and GPRS RTU technology, the valve chamber of the system realizes unattended monitoring automation, and improves the safety and automation level of the whole pipeline system The labor intensity of workers' patrol inspection is reduced, the measurement is more accurate, and the operation cycle of the equipment is prolonged. With the development of science and technology and the improvement of environmental protection requirements, it is an inevitable trend for the petroleum industry to further improve the effect of centralized control, improve efficiency and realize distributed control.

Manager Wang

Manager Wang

OfficialAccounts

OfficialAccounts