Testing technology is the abbreviation of measurement and testing (experimental) technology. In the long-term development of science and technology and production, testing technology has tended to be perfect and mature. Generally, physical "quantity" and chemical "quantity" have suitable testing methods. However, most of the traditional testing methods are only suitable for static measurement of various quantities (the measured quantity does not change with time or the frequency of change is not high). With the rapid development of science and technology, the new technological revolution has advanced human society from an industrialized society to an information society. This requires people to measure various parameters that change over time, even dynamic quantities with high frequency of change. At present, with the continuous development and maturity of electronic technology, semiconductor technology and computer technology, the testing technology of various dynamic quantities has also developed rapidly. Its high precision, high sensitivity, high response speed, as well as the characteristics of low energy consumption, small mechanism, continuous measurement, and automatic control make the testing technology develop to a new level. "Modern measurement and control technology" is the general term for this new comprehensive technology.

A complete measurement and control process should generally include:

The collection of information - done with sensors:

Transformation and transmission of information - done with intermediate transformation devices:

Processing and Analysis of Information - Processing with information processing equipment or computer software:

Display and recording of information - done with information display recording equipment or computer peripherals;

Regulation and control of information - through regulation, control and execution devices.

Modern measurement and control technology can and should adopt various modern new technologies in essentially every link of the measurement and control process. Especially after the combination of computer technology and testing technology, the structure, function and performance of each link in the measurement and control process can undergo revolutionary changes.

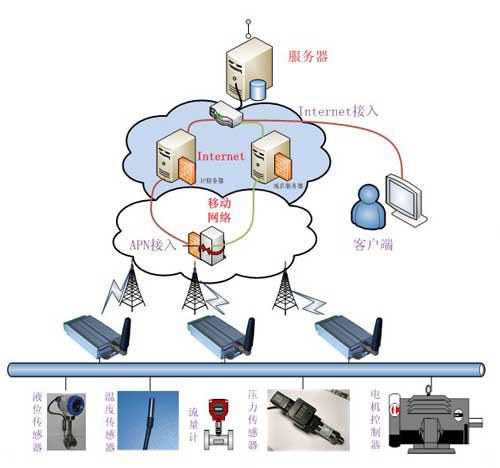

The temperature and humidity real-time monitoring system is mainly composed of temperature and humidity collector, temperature and humidity monitoring platform, controller (box), actuator, remote measurement and control end point RTU and control center software. The system adopts bus structure and modularization design. It can work independently and work online, which is convenient to set up and has good expansibility. The intelligent temperature and humidity collector adopts internationally advanced temperature and humidity sensitive components to transmit temperature and humidity parameters; the temperature and humidity control platform has a built-in microprocessor and intelligent design, which can work independently and facilitate networking. It can monitor and manage the work of each temperature and humidity controller, instruct each corresponding mechanism, and realize the detection and control of ambient temperature and humidity. At the same time, the communication function of the control platform enables it to accept the management and control of the upper computer and computer as a lower computer. Communication means such as carrier or telephone line (wireless) can be connected to the central network of the overall measurement and control system.

1) Temperature and humidity collector (signal acquisition):

It is used to measure the ambient temperature and humidity, using thermistor and polymer humidity sensitive capacitor for high-precision temperature and humidity measurement, intelligent design, and automatic calibration of temperature and humidity benchmarks.

2) Controller:

Accept the instructions of the temperature and humidity measurement and control platform, and control the start and stop of the actuator;

3) Executing agency:

Refers to equipment used to realize heating, cooling, humidification, dehumidification and other functions, such as heaters, refrigerators, humidifiers, humidifiers, etc.;

4) Monitoring platform:

It is an important part of the temperature and humidity real-time monitoring system, and it is the hub for contacting the temperature and humidity measurement and control and signal collector and the computer management and control center (host computer). On the one hand, it transmits the alarm setting parameters to the measuring head, and obtains the temperature and humidity values and switching variables of each point: on the other hand, it uploads the temperature and humidity values, status and switching variables to the computer management and control center. The inspection and control instrument provides the crystal display time, channel number, temperature, humidity, and ventilation and dehumidification status. The measurement and control platform provides real-time time by hardware, and the clock circuit includes a backup battery with a power-down protection function. The system time is not only displayed, but also used for printing, making the data of each point easy to query. The number of channel numbers depends on how many measuring heads the measurement and control platform can support at most. The temperature display depends on the test range, the humidity three-digit digital display, the range is 1RH% - 99RH%, and the resolution is 0.5RH%. The system status includes ventilation, forced ventilation, dehumidification, forced dehumidification, fault, lock, query. The temperature and humidity control values can be continuously set, and the work of the temperature and humidity measuring and controlling device can be automatically monitored according to the setting instructions to control the operation of the entire system. (host computer) work instructions. (optional with Chinese character printer).

5) Communication (link) module:

Connect the computer management and control center (host computer) and the measurement and control platform, so that the monitoring platform is integrated into the control and management center system of the overall calculation.

6) Computer Management Control Center

1. Multiple monitoring platforms can be displayed and detected remotely in real time: when the selected measurement and control platform is clicked, the computer will display and detect the temperature and humidity of each temperature and humidity collector of the platform'F in real time and in the form of tables and curves., relative humidity, adsolute moisture content, automatic ventilation and dehumidification state, forced ventilation and dehumidification state, and automatic control setting value, etc. Special color display is given to the value exceeding the standard.

2. The historical data of each measurement and control platform can be stored and analyzed, and processed accordingly. The juice computer management and control center stores the daily data of each temperature and humidity measurement and control and signal collector of each measurement and control platform. Every time the software is started, the software will automatically read out the historical data from the measurement and control system and calculate it.

1) The system adopts a bus structure and is composed of building blocks. Multiple humidity measuring and controlling devices in a monitoring area can be connected with a cable. How many test points (temperature and humidity measuring and controlling devices) can be set up, and how many control points can be added;

2) The monitoring platform adopts liquid crystal display, which can read the humidity measured by the standby temperature and humidity controller, and the lower limit setting value of the control state-E, etc.;

3) The platform displays the current time year month day

4) The system has power-down memory function

5) The measurement and control platform may communicate through communication modules such as RS232, 485 bus or power carrier;

6) The system has a heat protection device through the flow, and has an anti-lightning protection module (to avoid fire);

7) System modularization design, easy maintenance, strong scalability and convenient networking;

8) The system can be connected to the computer network of the control center, and remote measurement and control can be realized on the computer.

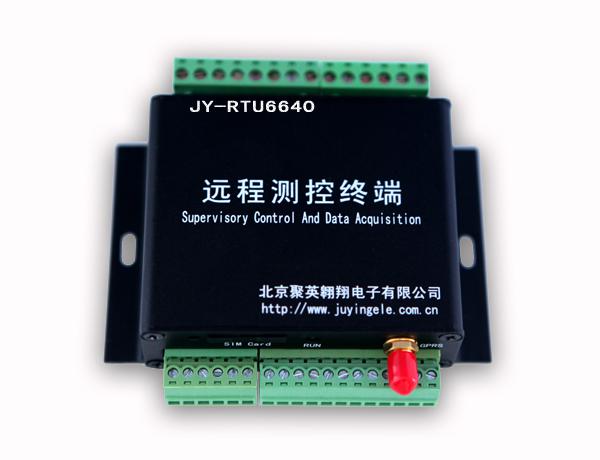

JY-RTU6640 provides equipment status indicators to facilitate equipment maintenance; wide voltage power supply range: 7V-30V; with RS232, RS485 (when 232 is also converted to 485, there can be two 485 channels); built-in large-capacity SPI-flash (capacity Optional 1Mbit-64Mbit) to realize long-term local storage of data (need to be customized); 6 channels of AD simulation input (12 bits), the input voltage is 0-30V, and can also measure 4-20mA industrial current signals; 6 channels Relay output control, 4-way optocoupler input and output control (the number of input and output bits is optional); built-in RTC, drop Electricity can be automatically timed, timed and fixed-point wake-up, which needs to be customized; efficient power management design, in occasions with strict power consumption requirements, to achieve low power consumption and energy saving, and to prolong working hours, which needs to be customized; transmission supports a variety of protocols, our company's custom protocols Perfect support with Modbus protocol (ASCII, RTU, Modbus TCP); Modbus slave working mode: standard slave, slave active return; data remote transmission supports GPRS, Ethernet, etc.; data transmission adopts GSM module to realize functions:

Automatic reconnection of GPRS disconnection; up to 6 central servers can be connected at the same time as needed; support fixed IP, domain name resolution and APN private network addressing;

Support TCP, UDP, PPP, ICMP, DNS, FTP and other protocols;

The number of nodes supported, as long as the server resources allow, is theoretically countless;

Reduce the cost of wiring and the trouble of construction;

Support SMS data transmission, SMS parameter configuration function;

Support phone and SMS wake-up function;

The data transmission adopts the Ethernet module to realize the functions:

Support 10Mbps/100Mbps two ways to access the Internet, the data transmission speed is accelerated, suitable for large data transmission;

Support TCP, UDP, PPP, ICMP, DNS, FTP and other protocols;

The number of nodes supported, as long as the server resources allow, is theoretically countless;

According to the needs of the server, the protocol can support more abundant;

Support network data wake-up function;

Support dedicated software for local and remote parameter configuration and maintenance;

Support local and remote firmware upgrades;

As shown:

Ethernet is currently the most widely used local area network transmission method. It uses baseband transmission to achieve 10m/100m/1000m network transmission through twisted pair and transmission equipment. Due to the wide range of applications, major network equipment manufacturers have devoted great energy to the research and development of such technical products, and the technology continues to innovate. From the initial shared 10m transmission technology on coaxial cables, it has developed to the current 100m or even 1000m transmission technology and switching technology on twisted pair and optical fibers. It is certain that Ethernet technology will continue to develop and improve at a higher speed. At present, basically all local area networks use Ethernet, and most of the subnets in large-scale network systems also constitute Ethernet. From the application point of view, various applications such as office automation, securities, campus networks, and control systems use Ethernet. As the main communication and transmission method, it is widely used. It is foreseeable that Ethernet will still be the mainstream technology in the future local area network. With extensive application and in-depth research, Ethernet technology has become fully mature, and there are no technical risks and unstable factors in adopting this technology.

Also due to the wide range of applications, large market sales, many product manufacturers, and fierce competition, the price of Ethernet products is low, and a very mature market has been formed, and the investment of application units in building networks has been limited to a low level.. From the perspective of engineering implementation, the integrated wiring system, which has been widely used at present, provides a set of standardized operating procedures for the implementation of the network. According to the standardized operation, the performance of the system will be fully guaranteed, and the engineering cost of the system is also relatively low. Applied to intelligent communities, the total investment in network and construction is about 600 yuan to 800 yuan per household. All in all, Ethernet is a communication technology with advanced and mature network technology, strong real-time performance, wide application, stable performance and low price.

The whole system adopts the composition method of a distributed system that can realize multi-point monitoring and management and the architecture of master and slave. The software system consists of two relatively independent upper computer software and lower computer software parts.

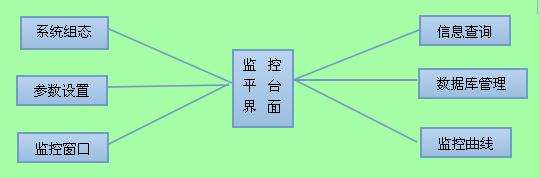

The structure diagram of the upper computer monitoring software module of this system is shown in Figure 4-8.

The host computer monitoring software mainly realizes the following functions:

① Serial communication: complete the communication configuration of the upper computer, and realize the communication between the upper computer and the lower maple.

② Data display: Provide three-dimensional three-dimensional chart, curve chart and table display.

③ Data storage: The real-time data (including the most husband value, the minimum value, the average value) is stored in a historical data table of the database according to the user's requirements; the data can also be exported to a file and saved to a text file in the form of text.

④ data search: allows users to query real-time data and historical data or analyze trend curves according to the situation.

⑤ Data printing: According to user requirements, print real-time data and historical data in tabular form.

⑥ Abnormal alarm: When the real-time temperature and humidity data exceeds the set upper and lower limit temperature and humidity values, the alarm bell rings.

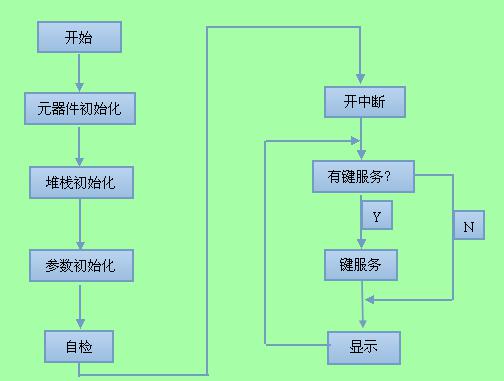

⑦ System settings: In order to ensure that the user can run well under any circumstances, the user is allowed to set the system's measurement time interval, upper and lower limits of temperature and humidity, save time interval, login user name, password and other parameters. The host computer application software includes 4 main modules: main program, receiving interrupt subroutine, display subroutine, and data dump subroutine.

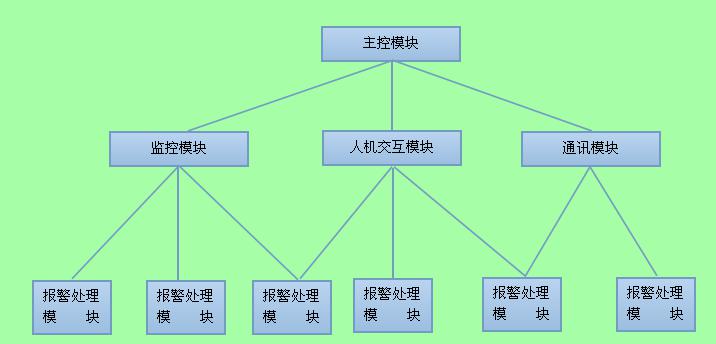

The main control module of the lower computer of the system completes real-time monitoring and management tasks through the monitoring module, the human interaction module and the communication module. And all the work is divided into alarm processing, control decision-making, information display, command processing, parameter setting and information output sub-modules to run. Figures 4-10 are the structure diagram of the software module of the lower computer.

The lower computer application software includes five main modules: main program, data collection subprogram, data processing subprogram, sending subprogram and display subprogram.

The main program flow chart is shown in Figure 4-11.

The remote temperature and humidity monitoring system solves the key technology of long-distance communication; analyzes the commonly used sensors. Four measurement structures (point structure, line structure, two-dimensional plane structure and three-dimensional three-dimensional structure) are summarized: the temperature and humidity control adopts the composite control based on Smith-fuzzy; compares a variety of communication methods, and realizes dual configuration (serial communication). and Kan card interface); and finally provide a complete set of software and hardware design solutions. It provides an effective and practical temperature and humidity measurement and control system for industry and families. On the one hand, it is an update to the current industrial temperature and humidity measurement and control technology, and on the other hand, it also provides conditions for people's family life to be more comfortable.

Manager Wang

Manager Wang

OfficialAccounts

OfficialAccounts